Our commitment to the Environment can be measured by how we run our organization.

Let us share our Sustainable Focus and experience with you to make your projects perform.

Devine Brothers Solar Farm

WE believe in the need for Sustainable Design – And we do it in house.

Devine Brothers took an active role by investing in our future and decreasing its carbon footprint. A solar field was designed and constructed on our facility roof, 22kw of power which produces 15% to 25% of our daily electrical consumption. We have generated over 500,000 kilowatt hours of electricity and have reduced our carbon footprint by almost 1,000 lbs of CO2.

Devine Brothers has invested in the renewable energy business by allocating resources to study the current technologies and skills that our mechanical trades would need to effectively participate. These include small privately owned gas fired cogeneration plants, geo-thermal systems, solar generation plants and wind turbines.

Mary Devine / Keystone Elementary

Energy Efficiency delivered – Geo Thermal to the Max

Devine Brothers constructed the mechanical portion of the new 90,000 square foot elementary school in Croydon Pennsylvania that incorporated 168 Geothermal Wells, each 500 feet deep, 66 classroom water source heat pumps, 6 rooftop/indoor water source heat pumps and a high efficiency condensing boiler system to temper the loop. Through its sister BAS company, Dynamic Control Systems, a fully automated Johnson Controls BACnet integrated Building Automation System was provided and commissioned. Devine Brothers, as the turnkey HVAC system integrator, provides backend support for all the installed product through offsite BAS Monitoring for the owner, Bristol Township School District.

EE Hub PSU – Philadelphia Naval Ship Yard

Energy Efficiency Innovation Hub for Penn State University

This project demonstrates the two opportunities in Sustainable Design – Greenfield and Retrofit projects. At adjacent locations within the Philadelphia Navy Yard, Penn State University renovated the old Naval Natatorium into a building retrofit laboratory to study the efficiencies of numerous innovative and diverse HVAC technologies with a goal of increasing awareness of Sustainable Design technologies. The HVAC work was performed by Devine Brothers and the Building Automation System with advanced measuring verification was designed and installed by its sister BAS company, Dynamic Control Systems. The systems employed were variable refrigerant flow (VRF) heat pumps; a dedicated outside air unit (DOAS); passive and active chilled beams; perimeter baseboard and panel radiation; fan powered VAV boxes, series and parallel; packaged gas/electric DX rooftops; These different technologies were used so that their energy usage could be studied and compared. The adjacent building that was constructed is 7R. This building was essentially a new structure using 48 geothermal wells in along with water source heat pumps. This enabled the PSU EEB Hub team to study these energy efficient lead edge technologies, utilizing the same monitoring system, in the context of a new and innovative building facility.

Rittenhouse Claridge Co-Generation Project

Retrofit Energy Efficiency thru Financial Engineering

Recent developments in gas turbine technologies along with the push for improved building efficiencies has led to many opportunities for cogeneration projects. Devine Brothers strives to be a leader in its industry and worked in a design build partnership to furnish and install (3) TECOGEN gas fired turbines with Low Emissions technology. These units are, in addition to their electrical output, capable of providing 1,533,000 BTU/hour of heating capacity that is used to heat the 28 story apartment building or to provide the domestic hot water supply. This use of the cogeneration plant provided for a capital improvement for the facility alleviating this owners need to replace aging steam boilers. The project incorporates an advanced monitoring and reporting control system that is optimized remotely by the third party owner / operator – designed by Devine Brothers and its sister BAS company, Dynamic Control Systems.

SECCRA – South East Chester County Refuse Authority

Greenhouse Gas Reduction with Energy Benefits

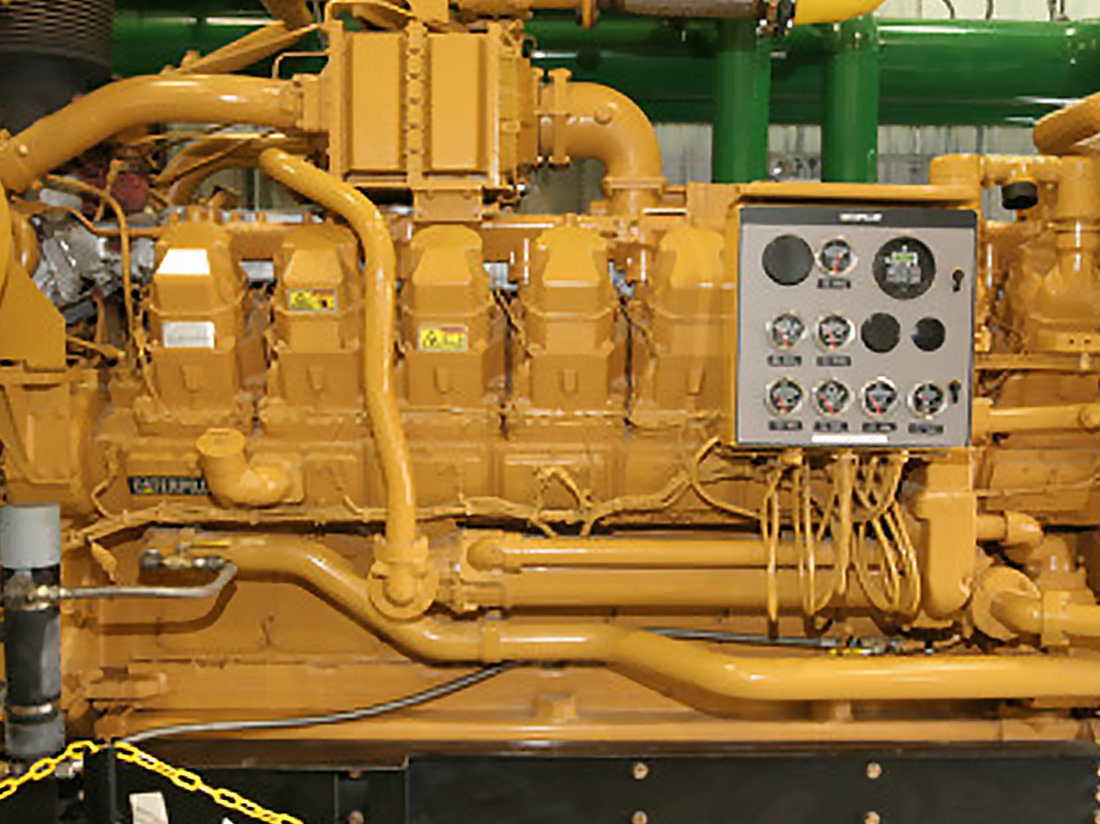

This Project is a waste product transformation into a source of energy. In the past the refuse Authority use to remove and burn the methane which was a byproduct of decomposing organic vegetation. This flammable gas was a hazard to the refuse authority and the methane is a greenhouse gas with a heat trapping signature thirty times that of CO2.

The SECCRA system as designed collects the methane that was built up under the landfill surface. The methane is then dewatered and compressed as a fuel source to power (2) engines/generators which provide electricity to sold back into the electrical grid. The project solved many existing environmental problems and provides a source of revenue for the Waste Authority.

Commadore Barry Elementary School

Excellence in Education coupled with Excellence in Energy Efficiency

Made possible with integrated “state of the art” systems. The project called for two hi efficiency oil-free magnetic bearing chillers with both variable speed chilled and condenser water pumping., TROX displacement classroom ventilation – efficiently conditions the room while effectively removing pollutants. Rainwater harvesting and storage facility complete with ionization disinfection that delivered non-potable water for water closet and urinal flushing as well as site irrigation.

Commodore Barry Elementary achieved a LEED Gold Certificate by the USGBC.